Offsite manufacturing (OSM) has become a very important practice in the delivery of facility builds for the advanced technology, data centre and life science industries. With the unique and challenging demands of these projects, the most innovative construction contractors have been leveraging OSM over the last decade or so to meet tight budgets and schedules. In this article we will explore the many advantages of this practice along with how the work can be tracked and some examples of its successful application.

So what is offsite manufacturing? It is the process of planning, designing, fabricating, transporting and assembling building elements for rapid site assembly to a greater degree of finish than in traditional piecemeal onsite construction. Numerous examples demonstrate elements that gain advantages from OSM including structural, modular construction, manifold valve skids, pipe spools, pipe racks, multi-trade prefabrication, med-gas valve boxes, trestles for utilities, cabling etc.

The top contractors have grown wise to the clear advantages of moving the building process away from the physical site and into their own controlled factory environment where everything can be tracked and monitored by a software like EIDA from skid and modular construction to pipework fabrication. The following are some of the advantages to OSM.

Cost Savings

Cost savings are always a top priority in any major construction project and with OSM contractors can achieve economies of scale, reduce onsite man hours and labour costs and reduce equipment and machinery rental/lease costs. By centralising the production process in a well equipped and well run factory setting, production is faster, there is less waste, less wage costs involved and fewer mistakes. Fewer mistakes leads to less rework and the negative impacts on profitability. Also, because many of the prefabricated parts and pieces are designed to fit together seamlessly, there is less need for costly specialised expertise or knowledge.

Schedule

One of the most clear and cited advantages with OSM is the increased speed of construction and its positive impact on the schedule. Multiple trade contractors can be working off-site, year round and simultaneously on their different areas and can all be tracked and monitored with a construction management software like EIDA that provides intuitive logic ensuring activities are completed in sequence and assigned checklists are completed in full. That allows follow-on users to receive notifications of completed works and real time reports keeping all stakeholders fully up to date on progress and delivering on schedule.

Parallel activities means that there can be less of onsite footprint and a reduction in any weather related delays that would normally slow the onsite construction process. Certain materials can be managed and stored elsewhere, onsite logistics and planning becomes less complex and generally workers won’t be getting in each other’s way as much.

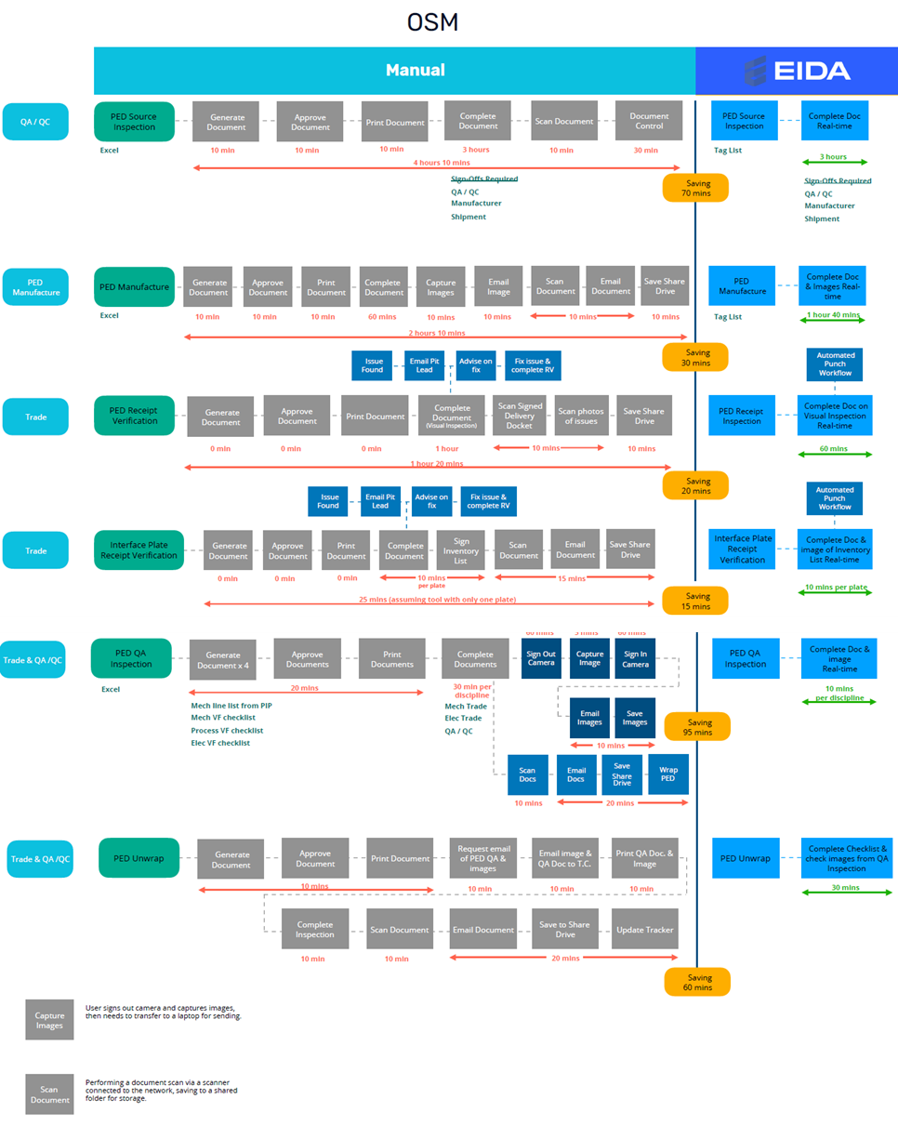

Contractors are marrying up the benefits of OSM with the cost and time savings achieved with software like EIDA. The below graph gives an indication of further time savings that can be achieved with EIDA’s OSM module.

An example of this in use for a large semiconductor fab build is where a team applied OSM to two sets of mechanical and electrical pipe trestles extending high above the manufacturing buildings. These trestles housed complex mechanical and electrical systems, designed for offsite prefabrication in multiple sections. Each section featured custom structural connections for efficient and secure field assembly. The mechanical and electrical systems were engineered to support prefabrication, incorporating flexible connectors and valves to streamline onsite installation. Upon completion, the trestle sections were hoisted into place and installed successfully.

Quality

With OSM, quality can be improved by being in a controlled and monitored environment. A large construction site by its very nature is in constant flux and there are hundreds of moving parts so applying factory quality procedures to the build means deliverables can arrive to site in showroom condition and can be flexible, scalable and often with the ability to be repurposed. It also creates new opportunities to install complex systems in areas with complicated space constraints.

To ensure quality is to the highest standard contractors are using software like EIDA to monitor vendor fabrication from spool fabrication through to installation and testing which is proven to drive productivity and increase quality. This leads onto factory acceptance tests (FAT’s) that can be digitised for execution and have punch items/defects assigned as needed ensuring all works are recorded and any remaining works addressed.

Safety

Controlled factory environments offer a more predictable and safe setting than construction sites, which can be affected by weather, decreased visibility, heavy machinery, moving objects, fall hazards, noise, airborne fibres and materials etc. The list is long and minimising exposure to risk is paramount to ensuring everyone goes home safe. That’s why OSM can be so valuable. Where components of a build can be worked on in a more safe and controlled environment, they should be.

Environment and sustainability

OSM can provide substantial environmental and sustainability benefits compared to traditional onsite such as significantly reducing material waste through practices like precision cutting and automated production, with leftover materials often reused or recycled. OSM can also reduce carbon emissions by consolidating production into a single facility, minimising the transportation needs, and reducing trips to construction sites.

Prefabricated components can be delivered in bulk and OSM facilities often utilise energy efficient methods with renewable energy sources, cutting overall energy consumption. From a sustainability perspective, which is becoming more baked into OSM processes, the use of more eco friendly materials like recycled steel and lower carbon concrete and modular designs that can be disassembled and reused are becoming more prevalent. It also reduces noise, dust, and waste at construction sites and overall environmental disruption which helps improve the surrounding community relations.

OSM has proven to be a game changing approach for large and complex builds, offering a multitude of benefits that align with the demands of modern construction. From cost savings and accelerated schedules to enhanced quality, safety, and sustainability, OSM addresses the key challenges of traditional onsite construction methods. By leveraging controlled factory environments, innovative tools like EIDA, and cutting edge prefabrication techniques, OSM allows contractors to achieve enhanced efficiency, precision, and sustainability.

As industries like advanced technology, data centers, and life sciences continue to push the boundaries of complexity in facility builds, the adoption of OSM helps ensure that projects can meet tight timelines and budgets without compromising on quality or safety. The integration of digital tracking and monitoring further enhances transparency, accountability, and productivity, making OSM not just a construction method but a forward thinking solution for the future of the built environment.

If you would like to hear more about how EIDA can track offsite project works for a full project view, talk to our expert team today.