Track off-site project works for a full project view. From skid and modular construction to pipework fabrication.

Multiple trade contractors can be assigned off-site manufacturing works and progress via intuitive logic, ensuring activities are completed in sequence and the assigned checklists are completed in full.

Notifications alert follow-on users of completed works and real-time reports ensure all stakeholders are kept fully up to date, delivering on schedule manufacturing.

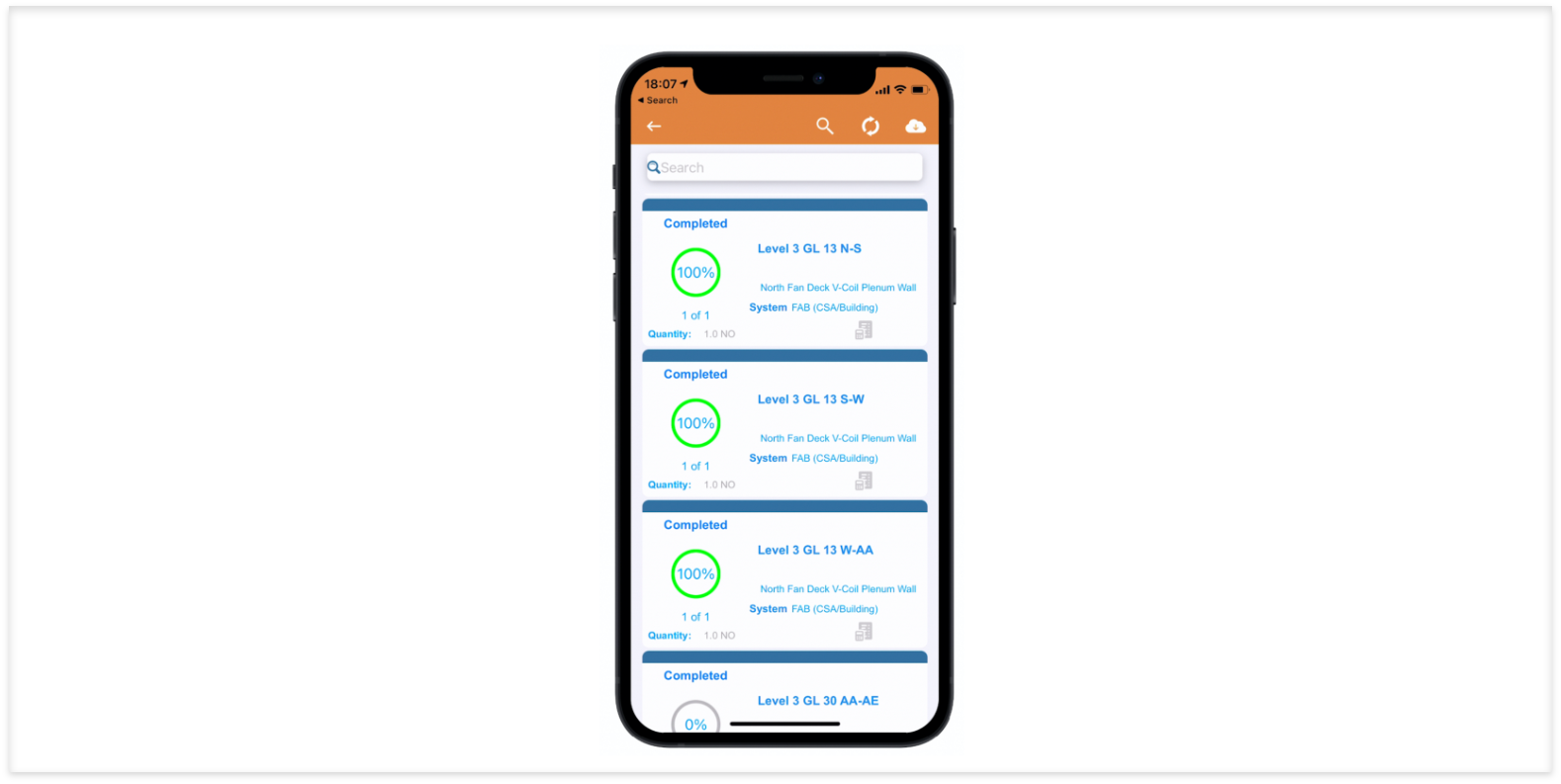

Modular Construction

Tracking progress and driving quality

All off-site manufacturing activities are connected to predefined quality checklists, ensuring all works are validated prior to site delivery for installation. Powerful capabilities include:

- Multi-disciplinary, CSA, electrical, mechanical activity tracking via mobile device

- Quality acceptance sign-off prior to delivery

- Trade contractor testing results and checks

- Receipt inspection checks performed upon delivery to site

- P6 schedule integration

- Create and manage punch items/defects (integrates fully with EIDA’s construction & commissioning features)

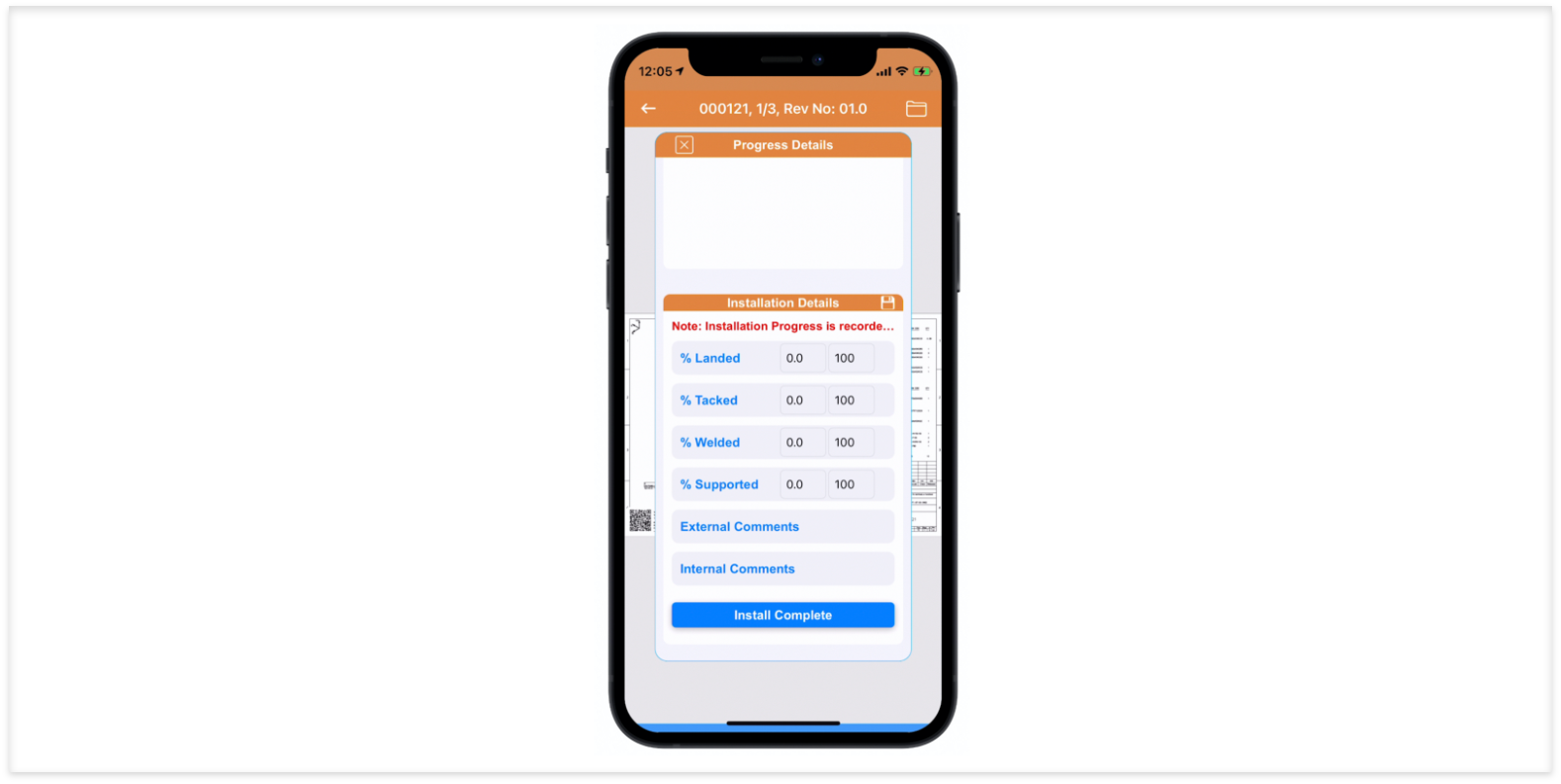

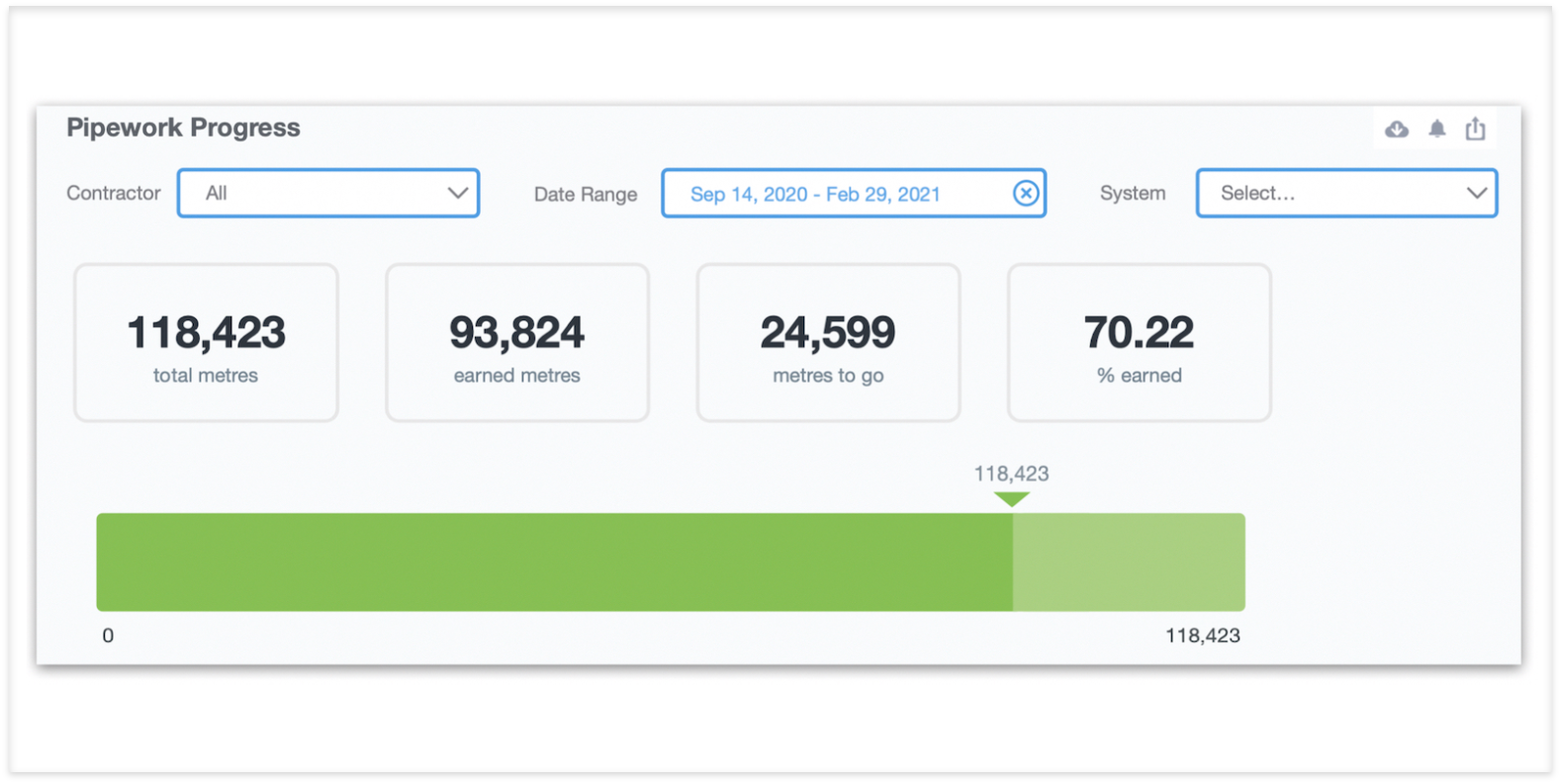

Pipework

Complete monitoring of vendor fabrication

From spool fabrication through to installation and testing, this feature is proven to drive productivity and increase quality.

Fabricated spools can be scanned in bulk via a bluetooth scanner and dispatched to site for installation. Functionality includes:

- Bulk import of isometrics and associated metadata

- Link progress to model (BIM)

- Update fabrication & installation via mobile device (QR code scanning)

- P6 schedule integration

- Links to weld history module

- Logistics module proven to eliminate loss and refabrication of previously delivered spools to site

- Real-time reports: earned metres by system, area, package, progress v schedule trade contractor performance

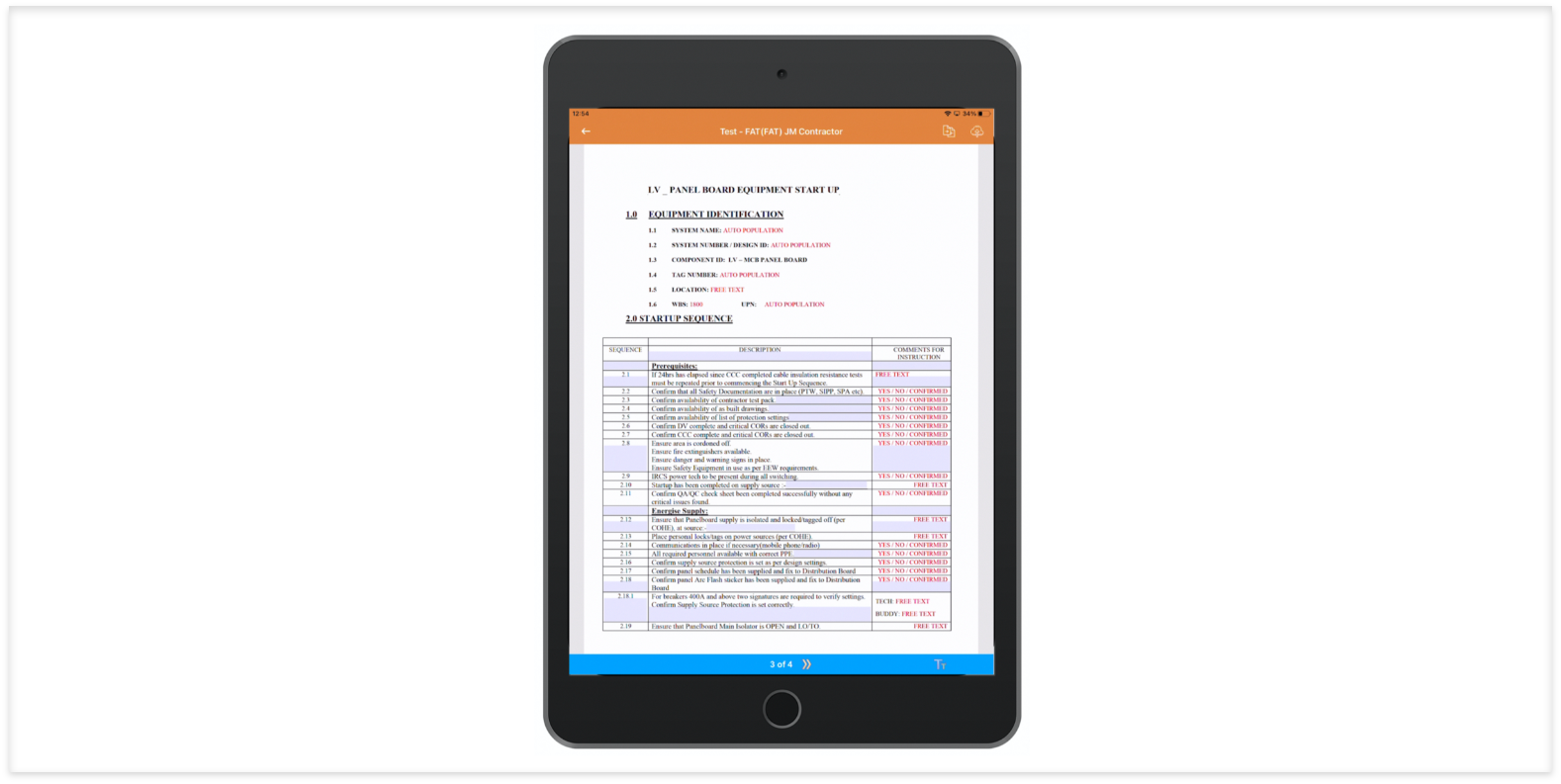

Factory Acceptance Tests (FAT)

Digitizing complex procedures for mobile use

Digitize FAT checklists for execution and assign punch items/defects as needed, ensuring all works are recorded and any remaining works addressed.

The latest technologies allow for FAT’s to be conducted online via an integrated camera. Saving travel time and costs, while also enabling the right people to attend more FAT’s. Users attending can annotate the required checklist items to sections of the recording. For those who cannot attend, recordings of FAT’s are easily retrieved within EIDA.