The largest construction projects, from semiconductor fabs and data centers to battery gigafactories and pharmaceutical facilities, come with enormous complexity. They involve dozens (sometimes hundreds) of trade contractors, thousands of tasks, design changes, ongoing inspections, test procedures, and what can feel like endless coordination meetings. With so many moving parts, staying aligned isn’t just a challenge, it’s one of the best opportunities for trade contractors to stand out.

When alignment slips though, things can get messy quickly. Schedules slide, rework piles up, systems clash, communication breaks down, inspections get missed, documents disappear, and teams get frustrated. But with the right mix of process, digital tools, and communication habits, trade contractors can turn all that complexity into something predictable and become the partners GCs and clients trust the most.

This article explores why misalignment happens, what “alignment” really means, and how trade contractors can maintain clarity and accountability from start to finish.

The challenge of alignment on large projects

It’s no surprise that the larger projects amplify every coordination risk that shows up on smaller jobs. With multiple subcontractors, teams, trades, vendors and suppliers all working within overlapping scopes and timelines, the chance of miscommunication grows quickly.

Schedules are usually tight, and when multiple trades are working at the same time, there’s very little room for error. Designs continue to evolve, and late changes can suddenly invalidate work that’s already been completed. Data is often scattered across different systems, templates, spreadsheets, or even manual forms, making it hard for teams to stay on the same page. And when accountability isn’t clear, issues can slip through the cracks or get duplicated.

In an environment like this, even minor missteps, a missed RFI or inspection, an outdated drawing, an incomplete checklist, the wrong approver etc, can snowball into days or even weeks of lost productivity.

Defining “Alignment” for trade contractors

Before getting into software, tools or workflows, it’s important to understand what alignment actually means on a large and complex project.

Alignment starts with shared milestones. Everyone should clearly understand the key dates, the sequencing dependencies, the commissioning readiness targets, and the requirements for turnover packages. When different teams operate with different milestones in mind, everything down the line becomes more difficult.

Alignment also depends on role clarity. Every trade contractor should be clear on who’s responsible for collecting field data, approving inspections, closing issues, and communicating status updates to the GC or the client. When handovers and responsibilities are well defined, delivery becomes more predictable and schedules become more reliable.

Digital Coordination

The days of managing progress on large projects with spreadsheets are (or definitely should be) firmly in the past. Teams on these projects need real-time visibility, traceability, and a way to organise and communicate without creating more work for each other.

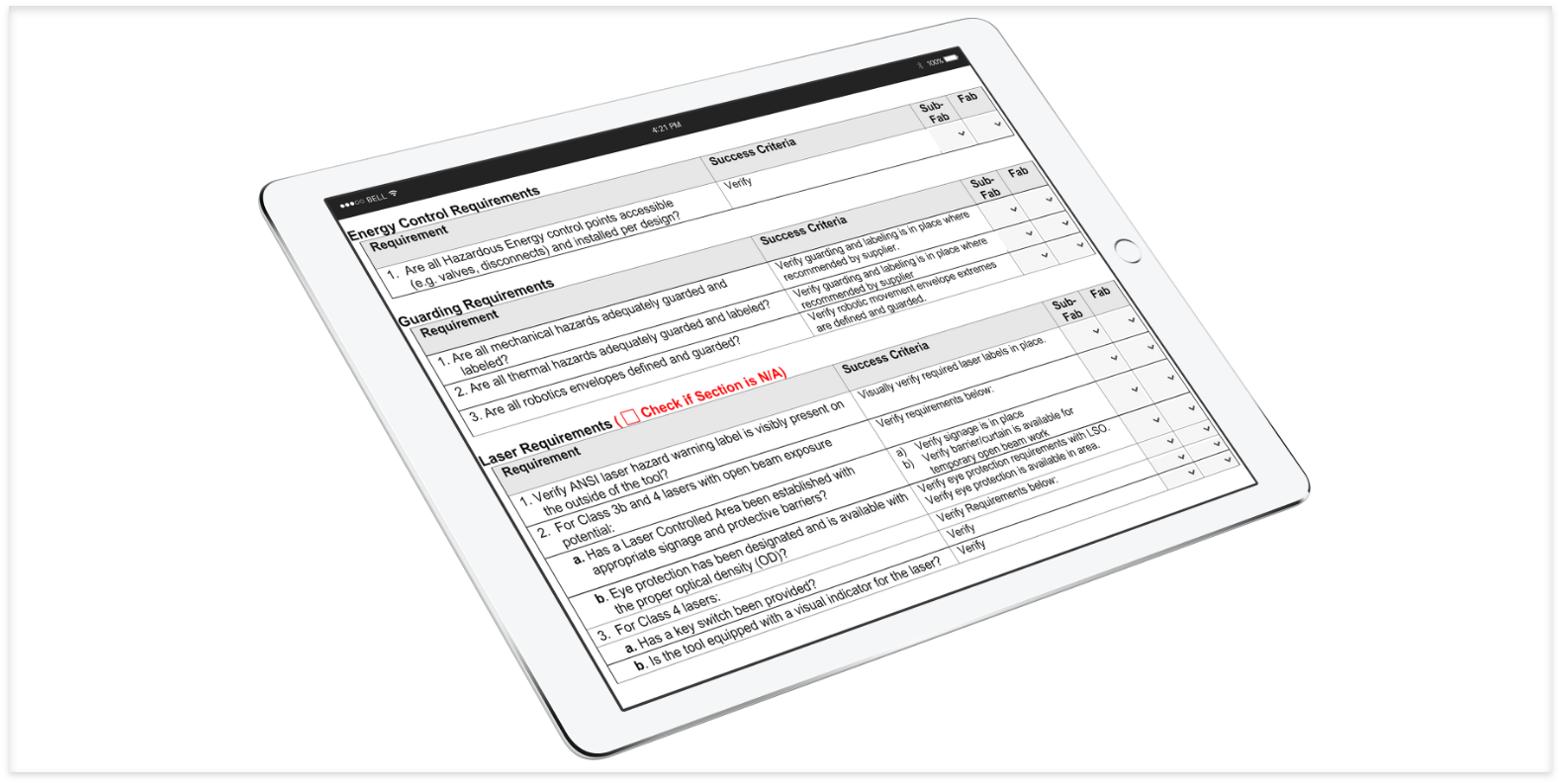

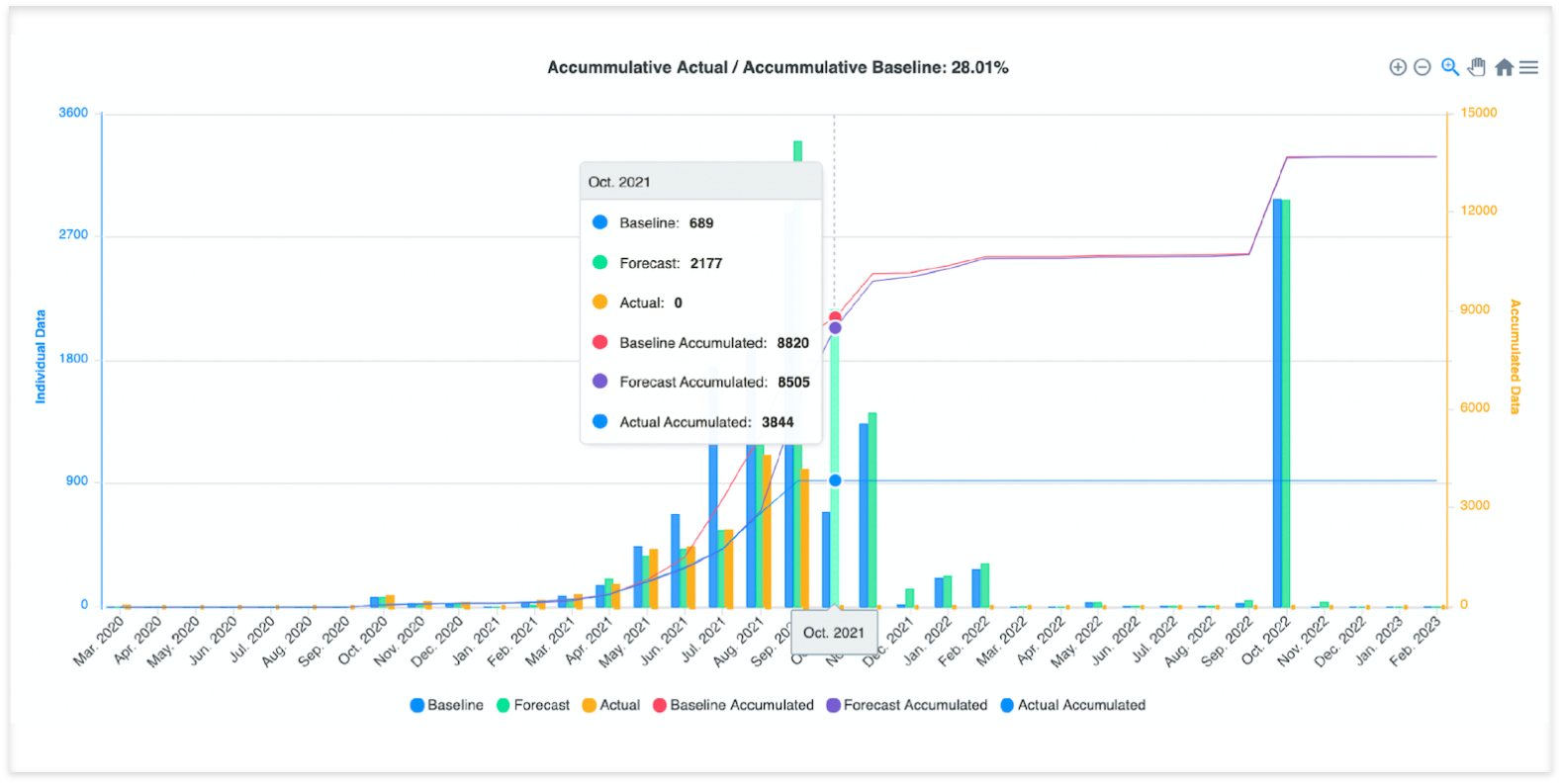

That’s where the most advanced construction management, turnover and commissioning software like EIDA comes in. It digitises, connects and streamlines every facet of construction where stakeholders can track tasks, approvals, and issues, and see what’s still open, what needs attention, what’s overdue, and what’s already been completed or approved. No one has to ask, “Did we finish that?” because the answer is right there.

Digital platforms like EIDA also eliminate the lag of manual reports. Instead of daily or weekly summaries, teams can update instantly with photos, status changes, and auto generated audit logs, all visible to everyone who needs to know.

Most GCs and clients also expect documentation to live within platforms like EIDA so there is a clear map and process when it comes to turnover and data stops getting siloed and important details don’t slip through the cracks.

Digital coordination isn’t just a nice to have anymore it’s a need to have and essential to staying aligned.

Site-level communication practices that actually work

As we know technology alone won’t solve alignment. Real alignment comes from combining software with consistent communication and collaboration on-site.

Daily “huddles” are quick, structured morning meetings, that help everyone stay on the same page by clarifying the day’s priorities, clearing roadblocks and bottlenecks early, and making sure the different trades understand how the sequencing fits together. When teams do this consistently, there are less negative surprises.

Digital check-ins give on-site teams a simple way to share daily progress updates, installed quantities, weld logs, pipework completion, QC checks, and issues with photos. This instantly keeps all the relevant stakeholders and other trades in the loop.

Visual dashboards help make complex information easier to digest. When teams can clearly see percent complete, system readiness, outstanding QC items, or commissioning progress, they make better decisions.

And standardised templates, whether for daily reports, test packs, safety permits, RFI’s, submittals, QC forms, or functional tests save everyone time and reduce confusion by keeping documentation consistent across teams.

Leadership and culture

Even with great tools and processes, real alignment comes down to people.

A culture of accountability is key. Teams should not only complete their work but also report it accurately and on time. That means closing issues quickly, completing checklists fully, and logging required documentation every day rather than waiting until the end of the week or month or longer.

Key leaders on a project like Construction Managers, Document Controllers, QA/QC Directors etc who are equipped and trained to use digital tools become catalysts for alignment. They communicate faster, flag problems earlier, provide clearer updates, and help avoid unnecessary disputes and delays.

Teams also need to feel empowered to speak up when something doesn’t look right, whether it’s a design conflict, something out of sequence, or a system that’s not ready. Early warnings prevent late stage failures.

A good example of a positive culture delivering a highly successful project was on a large biomanufacturing project in Holly Springs which is the largest end-to-end cell culture manufacturing facility in North America. Throughout the build there was a positive working culture and honest and open relationships were built between the client, the GC and the trade contractors. With nearly 13M safe work hours logged and industry-leading modular and digital delivery methods applied, the project demonstrated what’s possible when client and partner relationships are built on transparency and shared purpose.

Culture might not be written on any drawings or schedules, but you definitely see it in the final results.

Building a foundation for predictability

As we have discussed, alignment isn’t really optional on a large and complex project, it’s essential. Trade contractors who invest early in clear roles, digital coordination, repeatable processes, and strong communication deliver more predictable and higher quality results.

Alignment isn’t just a project requirement, it’s a real competitive advantage.

With better visibility, tighter coordination, and a culture built on accountability, trade contractors can turn a mess into clarity and become the go-to partners on the most complex builds.

If you would like to hear more about how EIDA can help trade contractors to track progress, manage documentation, and deliver complete, verified turnover packages without the hassle, talk to one of our senior experts today.